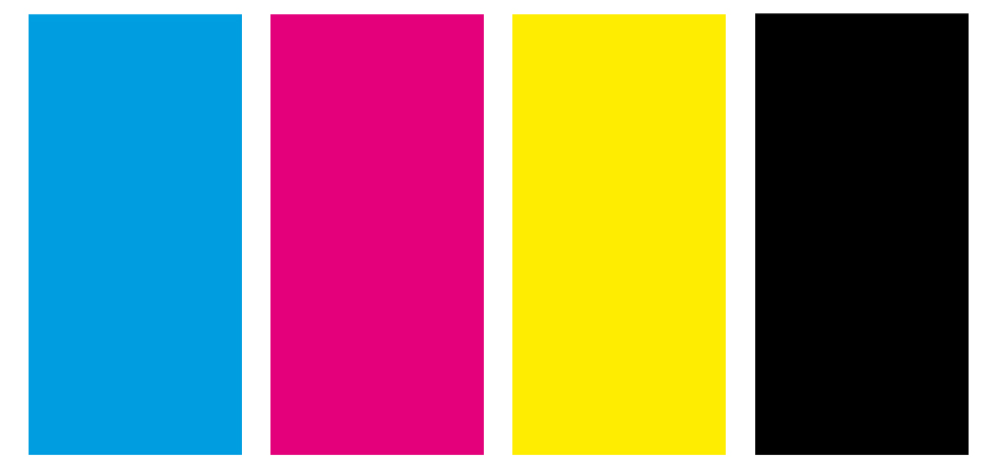

In the world of printing and color reproduction, CMYK stands as a cornerstone technology that has revolutionized how we produce colored materials. This comprehensive guide explores why this color model earned its distinctive name and how it became the industry standard for print production worldwide.

## The Origins of CMYK

Historical Development

The story of CMYK begins in the late 19th century with the evolution of color printing. While artists had long understood color mixing principles, it wasn’t until the industrial revolution that standardized color printing became necessary. The development of CMYK came from the need to reproduce full-color images consistently and efficiently in mass production.

The Science Behind Subtractive Color

CMYK operates on the principle of subtractive color mixing, which is fundamentally different from the additive color mixing used in digital displays. In subtractive color theory, colors are created by absorbing (subtracting) certain wavelengths of light and reflecting others. This process mirrors how we see colors in the physical world through reflected light.

Why These Specific Colors?

The selection of Cyan, Magenta, Yellow, and Black wasn’t arbitrary. These colors were chosen because they provide the widest possible color gamut when mixing inks for printing. Through extensive experimentation and scientific research, these four colors proved to be the most effective combination for reproducing the full spectrum of visible colors in print.

## Understanding Each Component

The Cyan Element

Cyan, the ‘C’ in CMYK, is a bright blue-green color that serves as one of the primary subtractive colors. It absorbs red light while reflecting blue and green wavelengths. This makes it crucial for creating blues, greens, and various cool tones in printed materials.

The Magenta Element

Magenta, represented by ‘M’, is a vibrant purplish-red that absorbs green light while reflecting red and blue. This color is essential for producing reds, purples, and pink tones in printing. Despite not being a spectral color, magenta plays a vital role in color reproduction.

The Yellow Element

Yellow, the ‘Y’ component, absorbs blue light while reflecting red and green wavelengths. It’s fundamental for creating warm colors and is the brightest of the primary printing colors. Pure yellow is also the easiest of the three chromatic components to produce consistently.

The Key (Black) Component

The ‘K’ in CMYK stands for “Key” color, which is black. While theoretically, combining cyan, magenta, and yellow should produce black, in practice, this often results in a muddy brown. Adding black as a separate component ensures deeper shadows and true black text.

Why ‘K’ for Black?

The use of ‘K’ instead of ‘B’ has historical and practical significance. ‘K’ stands for “Key” because black ink typically provides the key details in printed images. Additionally, using ‘B’ might have caused confusion with blue, hence the adoption of ‘K’ in the acronym.

## CMYK Color Technology

How CMYK Creates Colors

CMYK creates colors through a process called halftoning, where tiny dots of each color are printed in patterns. These dots appear to blend together when viewed from a normal distance, creating the illusion of continuous color tones.

### The Printing Process

In modern printing, each color is applied separately in layers. The precise control of ink density and dot patterns allows for the creation of millions of different color combinations. This process requires careful calibration and precise registration to ensure colors align properly.

Color Gamut and Limitations

CMYK has a smaller color gamut than RGB, meaning it can’t reproduce some vibrant colors that can be displayed on screens. This limitation is due to the physical properties of inks and the subtractive color mixing process. Understanding these limitations is crucial for designers and print professionals.

CMYK Color Mixing Principles

The principles of CMYK mixing follow specific mathematical and optical rules. Each color is typically represented as a percentage from 0 to 100, allowing for precise color specifications. For example, a deep purple might be created with C:30%, M:100%, Y:0%, K:0%.

## CMYK in Professional Printing

Commercial Printing Applications

CMYK is the standard for most commercial printing applications, from magazines and brochures to packaging and promotional materials. Its reliability and cost-effectiveness make it the preferred choice for large-scale print production.

Digital vs. Offset Printing

While both digital and offset printing use CMYK, they handle color reproduction differently. Offset printing typically achieves more precise color matching, while digital printing offers greater flexibility for small print runs.

Color Calibration

Proper color calibration is essential in CMYK printing. This involves regular maintenance of printing equipment, color profiling, and careful monitoring of ink densities to ensure consistent color reproduction across different print runs.

Print Quality Control

Quality control in CMYK printing involves various tools and techniques, including densitometers, spectrophotometers, and color bars. These help maintain consistency and accuracy in color reproduction throughout the printing process.

## CMYK vs Other Color Models

CMYK vs RGB

While RGB is designed for digital displays, CMYK is optimized for printing. Understanding the differences between these color models is crucial for designers who need to prepare materials for both digital and print media.

CMYK vs Pantone

Pantone colors are spot colors that can provide more consistent and vibrant results than CMYK for specific colors. However, CMYK remains more cost-effective for full-color printing.

CMYK vs Hexachrome

Hexachrome was an expanded color system that added orange and green to CMYK, but it never gained widespread adoption due to increased costs and complexity.

Modern CMYK Standards

Today’s CMYK standards include various color profiles and specifications designed to ensure consistency across different printing systems and substrates.

Conclusion

The name CMYK represents more than just an acronym for four colors; it embodies a sophisticated system that has revolutionized color printing. Its development and continued use reflect a deep understanding of color theory, practical printing requirements, and the physics of light and pigments. As printing technology continues to evolve, CMYK remains the foundation of color reproduction in the printing industry.

FAQ

1. **Can CMYK produce every color visible to the human eye?**

No, CMYK has a limited color gamut compared to what humans can see, especially when it comes to very bright or fluorescent colors.

2. **Why not use RGB for printing?**

RGB is an additive color model designed for light emission, while CMYK is subtractive and better suited for ink-based color reproduction on physical materials.

3. **Is black really necessary in CMYK printing?**

Yes, while theoretically CMY could create black, using actual black ink provides better depth, saves ink, and ensures clearer text and details.

4. **How many colors can CMYK produce?**

CMYK can theoretically produce millions of different color combinations, though the exact number depends on the printing technology and materials used.

5. **Why do colors look different on screen versus in print?**

This difference occurs because screens use RGB (additive) color while printing uses CMYK (subtractive) color, resulting in different color gamuts and reproduction capabilities.